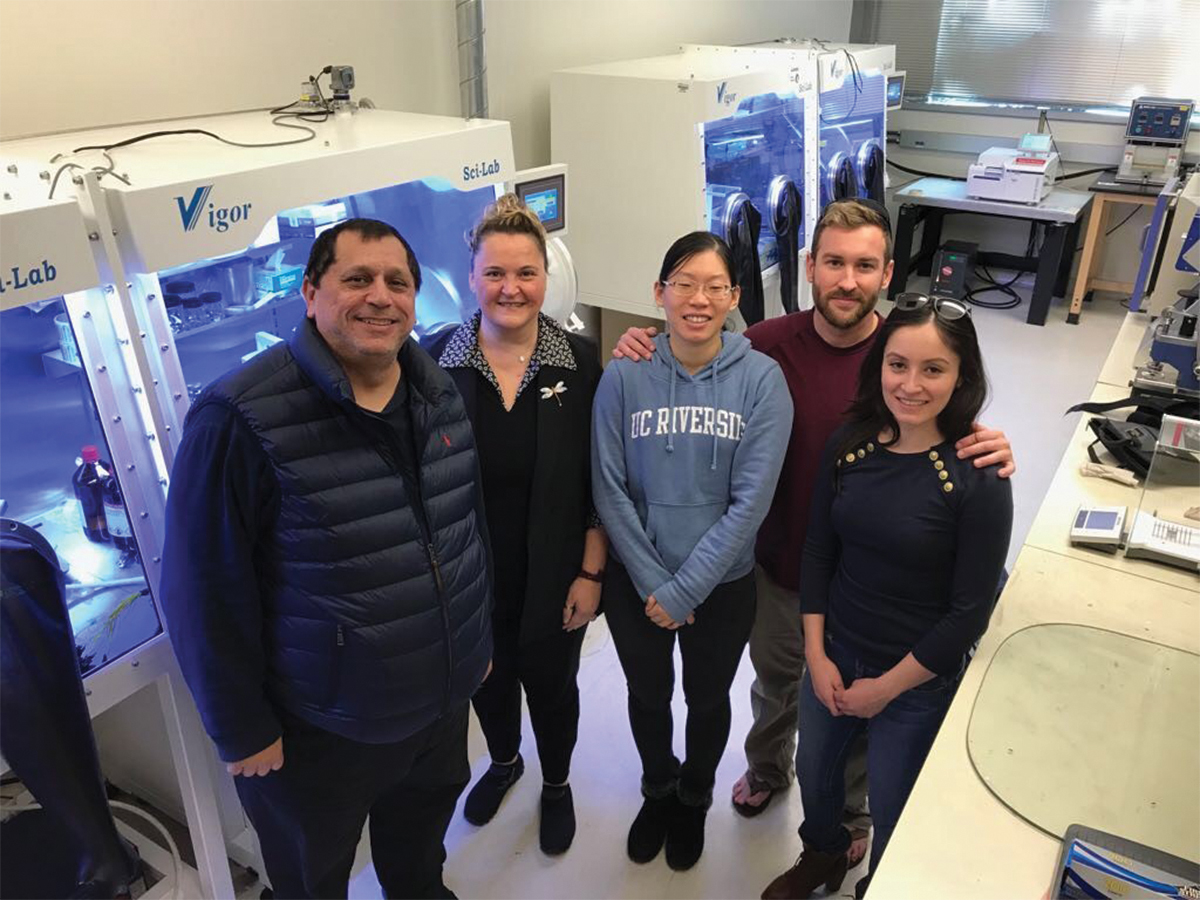

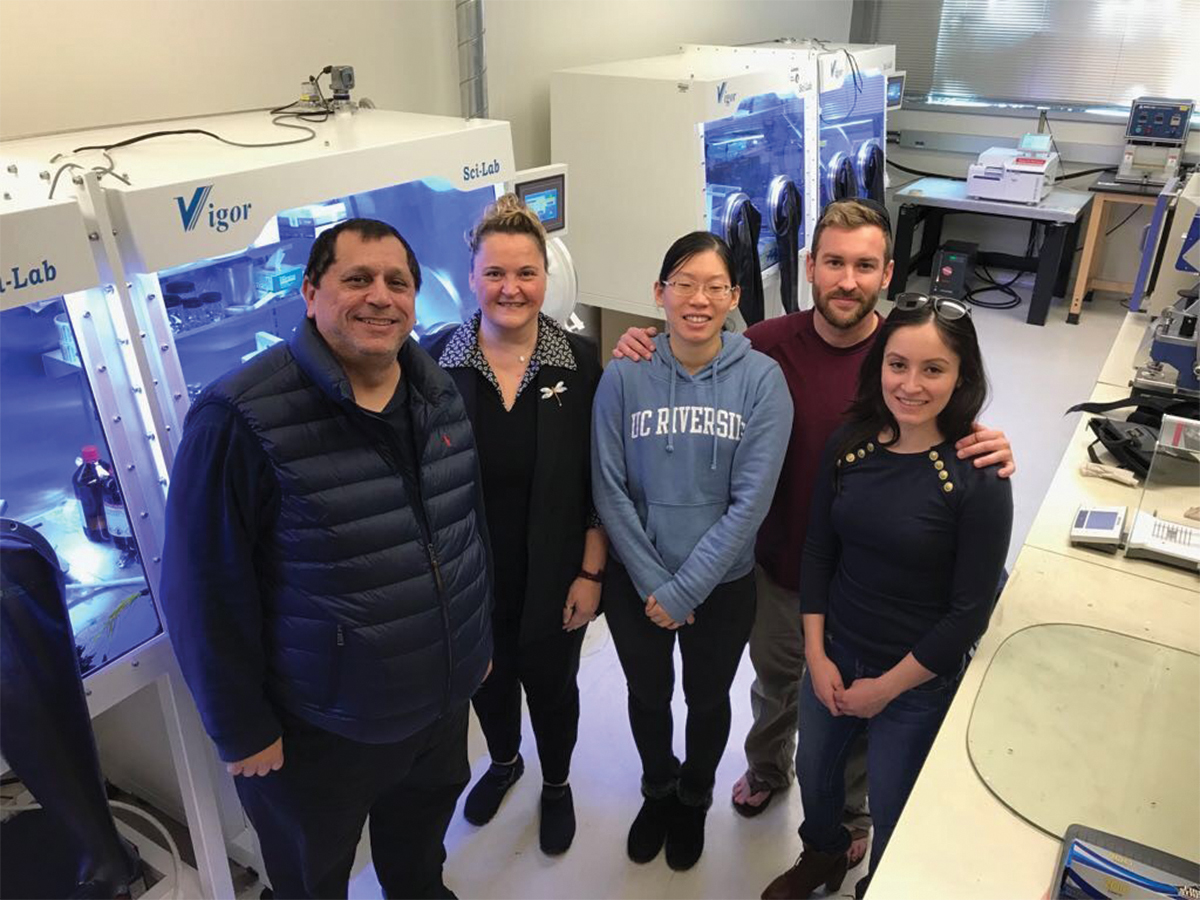

Researchers at the Bourns College of Engineering have improved their technique for producing more efficient lithium ion batteries using sulfur and silicon electrodes. This project was led by Cengiz Ozkan, a professor of mechanical engineering, and Mihri Ozkan, professor of electrical and computer engineering, with contributions from graduate students Rachel Ye, Jeffrey Bell, Daisy Patino and Kazi Ahmed.

According to Ye, this new battery will yield better performance compared to the regular commercial counterparts which traditionally use graphite or pure lithium as the anode. The team has only been able to use a limited amount of the silicon and sulfur capacities but they have high hopes for the materials’ theoretical capabilities in the future when they are able to further optimize their batteries. Likewise, the team has created an easier method of inserting a lithium source into the sulfur silicon system instead of the standard process of prelithiation, which is time consuming and unstable.

One problem the team has faced when creating the fuel cell was building the infrastructure of the battery itself without resorting back to the traditional prelithiation method. Ye shared in an email interview that “none of the architectures worked” unless the lithium was inserted in direct contact with the current collector for easy electron access. Once they achieved that, the team was able to control the amount of lithium inserted in the full cell battery.

In addition to its performance, the team’s fuel cell has proven much safer than the standard fuel cell today. “These pure lithium anodes (in current sulfur fuel cells) have a lot of problems such as they are easily corroded, and they can form dendrites which will short the battery,” said Ye in an email interview. “Thus if we optimize our sulfur silicon full cells, we will be able to produce a safer version of commercialized sulfur full cells.” Not to mention, the abundance in sulfur and silicon materials provides an economical and environmentally friendly solution to the growing demand of electric fuel cells for electric vehicles and plug-in hybrid vehicles.

However, according to Bell, in spite of the huge potential these batteries have on these appliances, the team does not expect the full cells to be commercially exploited for another five to 10 years.

The team plans on improving their full cell in regards to the architecture, the electrodes and the weight balance between the electrodes and electrolytes, optimizing their batteries to be more efficient with better performance. Furthermore, the team hopes to expand on sulfur technology.

“These other sulfur technologies may include flow cells or sodium ion cells or traditional lithium sulfur cells utilizing novel cathodes or additives,” said Bell in an email interview. “As our understanding of sulfur and silicon systems deepens, we’ll be experimenting more and more with new systems and materials.”

Further information on their findings can be found in the scientific journal Nature Scientific Reports titled “Advanced Sulfur-Silicon Full Cell Architecture for Lithium-Ion Batteries.”

The Ozkans were not available for a request for comment.